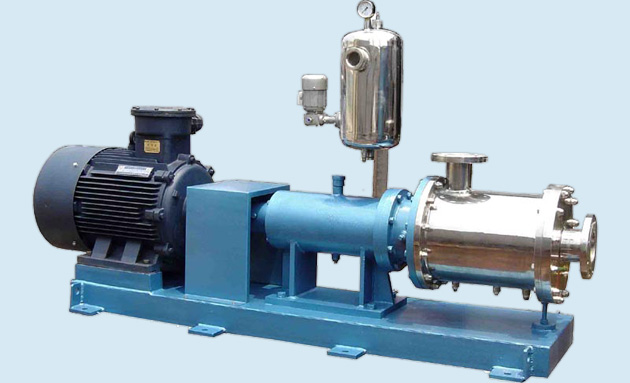

In-line Emulsifying Machine

Application

Application Working principle

Working principle Introduction

IntroductionThere are 3 series of the machine:1. Emulsifying pump (with 1 stage ) 2. Emulsifying pump (with 2 stage ) 3. Emulsifying pump (with 3 stage )

It will well meet your demannd.

|

|

|

|

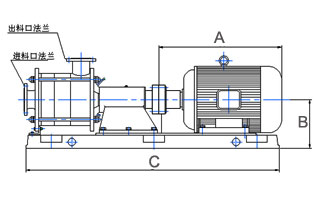

Outline of in line emulsifier (with 3 stages) |

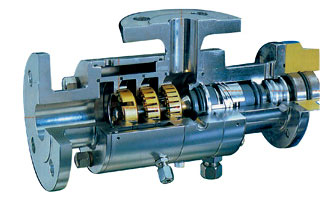

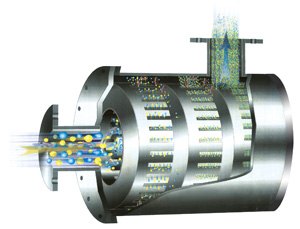

Inside structure of in line emulsifier (with 3 stages) |

| There are 3 groups of rotors and stators, which shear and disperse the materials. | |

CONFIGURATION

1.Temperature: -10℃---+140℃

2.Noise: <85dB(A)

3.Elctric source: 380V 50HZ

4.Power: 1.1KW---75KW

5.Scavenging: CIP/SIP

6.Slew time: continuous

7.Heating or cooling sleeve

8.Frequency control motor

9.Mechanical cooling recycle system

Detialed description and working principle

Technical Parameter

- Temperature:-10℃ to +140℃

- Noise Level:<85dB(A)

- Power:380V 50HZ

- Configuration Power:1.1KW to 75KW

- Cleaning:CIP/SIP

- Rotation time:continuous

- It can be equipped with working chamber jacket (heating or cooling)

- It can be equipped with explosion-proof motor(EX)

- It can be equipped with frequency conversion motor, cooling circulation system can be equipped with mechanical seal

- It can be equipped with explosion-proof motor(EX)

- It can be equipped with frequency conversion motor, cooling circulation system can be equipped with mechanical seal

Technical parameter

Emulsifying pump (with 1 stage )

|

MODEL

|

POWER (Kw)

|

SPEED (rpm)

|

CAPACITY (m3/h)

|

DIMENSION(mm))

|

INLET

|

OUTLET

|

|||

|

A

|

B

|

C

|

D

|

||||||

|

GR4-1

|

4.0

|

2890

|

4

|

400

|

112

|

880

|

950

|

DN40

|

DN32

|

|

GR7.5-1

|

7.5

|

2900

|

7

|

475

|

132

|

1130

|

950

|

DN50

|

DN32

|

|

GR22-1

|

22

|

1470

|

25

|

710

|

180

|

1364

|

1035

|

DN80

|

DN65

|

|

GR37-1

|

37

|

1480

|

40

|

820

|

225

|

1600

|

1035

|

DN125

|

DN100

|

|

GR55-1

|

55

|

1480

|

80

|

930

|

250

|

1900

|

1035

|

DN150

|

DN100

|

Emulsifying pump (with 2 stage )

|

MODEL

|

POWER (Kw)

|

SPEED (rpm)

|

CAPACITY (m3/h)

|

DIMENSION(mm)

|

INLET

|

OUTLET

|

|||

|

A

|

B

|

C

|

D

|

||||||

|

GR4-2

|

4.0

|

2890

|

2

|

285

|

112

|

995

|

900

|

DN40

|

DN32

|

|

GR7.5-2

|

7.5

|

2890

|

4

|

475

|

132

|

1300

|

1050

|

DN50

|

DN50

|

|

GR22-2

|

22

|

1470

|

18

|

710

|

180

|

1536

|

1050

|

DN80

|

DN65

|

|

GR37-2

|

37

|

1480

|

30

|

820

|

225

|

1840

|

1050

|

DN125

|

DN100

|

|

GR55-2

|

55

|

1480

|

60

|

930

|

250

|

2157

|

1050

|

DN150

|

DN100

|

Emulsifying pump (with 3 stage )

|

MODEL

|

POWER (Kw)

|

SPEED (rpm)

|

CAPACITY (m3/h)

|

DIMENSION(mm)

|

INLET

|

OUTLET

|

|||

|

A

|

B

|

C

|

D

|

||||||

|

GR4-3

|

4.0

|

3000

|

2

|

323

|

100

|

897

|

900

|

DN40

|

DN32

|

|

GR7.5-3

|

7.5

|

3000

|

4

|

518

|

160

|

1196

|

1050

|

DN50

|

DN50

|

|

GR22-3

|

22

|

2890

|

18

|

766

|

200

|

1483

|

1050

|

DN80

|

DN65

|

|

GR37-3

|

37

|

1500

|

30

|

818

|

225

|

1705

|

1050

|

DN150

|

DN125

|

|

GR55-3

|

55

|

1500

|

60

|

930

|

280

|

2000

|

1050

|

DN150

|

DN125

|

REMARKS

the flow range refers to the medium "water"

If cyclic process used, we recommend to use intermittent high-shear dispersing emulsifier in conjunction.

If the materials need dealing with are high-temperature, high pressure, flammable, explosive, corrosive, please kindly provide precise parameters

if you deal with illiquid medium, you are recommended to match a pumping whose pressure ≤ 0.2MPa.

viscosity for each additional 1000mPax, nominal productivity will be reduced by 20%.

materials with viscosity of 3000mP must be pumped into, the pump should be used as a continuous pump.

When the material flow is samll, you’d better pay more attention to observations of temperature.

It is customizable according to your needs if detailed information provided.

The pink parameter is what we recommend to u.

Pls send us detailed inquiry, and I’d like to quote u the best price.